Starlinger & Co. GmbH., Austria

Starlinger is an innovative European engineering company specialising in machinery and process technology for woven plastic packaging production and PET recycling and refinement. The family enterprise, founded in 1835, has production sites in Weissenbach and St. Martin in Austria, as well as in Taicang, China. With an export quota of over 99.5 % Starlinger is a leading supplier of high-level technology to customers in more than 130 countries. Starlinger branch offices are located in Brazil, China, India, Indonesia, Russia, South Africa, Uzbekistan and the United States; in other countries the company is represented by agencies.

Plastics recycling, decontamination and refining

The product portfolios of the divisions Starlinger recycling technology and Starlinger viscotec comprise machinery solutions for the recycling, decontamination and refining of a wide scope of plastics such as PE, PP, PA, PS, BOPP, PET and many more. The recoSTAR recycling lines produce high-quality pellets from production or post-consumer waste from various applications, including film, sheet, fibre, non-woven, raffia, tape, bottle, or preform production. Starlinger PET recycling systems produce food-safe r-PET and are approved for use in food applications by many brand owners as well as various national and international authorities such as FDA (Food and Drug Administration, USA) and EFSA (European Food Safety Authority).

Starlinger viscotec specialises in PET and HDPE decontamination technology and provides equipment for the decontamination and IV increase of PCR flakes and pellets. The technology guarantees food-grade material that meets FDA and EFSA standards and can be directly used for food packaging production.

The newly developed viscoSHEET PET sheet line processes virgin PET, PIR (post-industrial regrind) and up to 100 % recycled PET, producing rPET sheet with guaranteed IV levels that meet FDA/EFSA levels for food-grade applications.

Leader in woven packaging production machinery

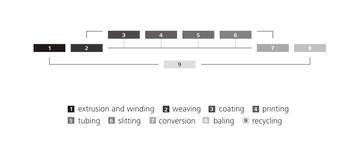

Starlinger is the world’s only A to Z supplier of complete turnkey plants for the production of circular woven plastic sacks. These sacks are used mainly for packaging bulk goods such as food grains, sugar, flour, animal feed, fertilizer and cement, but also for FIBCs, fabric for carpet backing, or geo-textiles. Innovative packaging product developments by Starlinger are the worldwide patented AD*STAR® block bottom valve sack for cement and bulk goods, as well as the PP*STAR® pinch bottom sack and the CB*STAR® carrier bag, both destined for end consumer applications. The woven*FFS® sack combines the efficient FFS (Form, Fill & Seal) filling method with the high strength and resistance of woven tape fabric. The latest innovation is the development of polyester tape fabric for heavy-duty applications such as FIBCs. PET tapes stand out for their high tenacity and high creep modulus as well as low thermal shrinkage, providing fabric and articles produced out of it with exceptionally high strength and long-term form stability.

The Starlinger product range covers all types of machinery for the production of modern woven polypropylene sacks.